Most office 3D Printers use FDM technology and they melt the printing material that comes in cable form. When the filament touches the printing surface it hardens, then more layers are printed on top of layers and the final object is formed. The most common types of 3D printing filaments are PETG, ABS (acrylonitrile butadiene styrene) and PLA (poly-lactic acid). These printing materials have some very different properties.

PLA / 3D Printing material, is produced from vegetable sources (maize, sugar beet). This thermoplastic material is non toxic, biodegradable and it doesn’t affect the environment in a negative way. PLA is a strong material and the right temperatures when using it for 3D Printing are between 180-220 °C. Printing using PLA offers a smooth object base but if adhesion needs reinforcement a heated bed at 50°C and painters tape can hold an object down effectively. PLA is generally rigid, with low heat deflection point (60C).

ABS / Very strong polymer plastic 3D Printing material that is also used for industrial purposes. ABS is also non-toxic. It prints at higher temperatures around 230-270°C. A heated bed and chamber are essential when printing ABS. Its a strong and somewhat flexible material, with good heat deflection properties (up to 100C).

PETG / is Somewhere in between the other 2, combines the elasticity, strength and heat deflection of ABS (90C), with the print ease of PLA. Ideal for tolerant and complicate parts.

Nylon, Wood, Metal, Flex etc. / Some printers can print a wide variety of materials with different strenth, flexibility and visual outcome. Nylon and Flex are not as easy to print and need much higher temperatures. Τhey are flexible and they are suitable for only certain designed objects. Wood and Metal 3D Printing Filaments are produced from recycled wood and metal filings and the final 3D printed object looks like wood or metal.

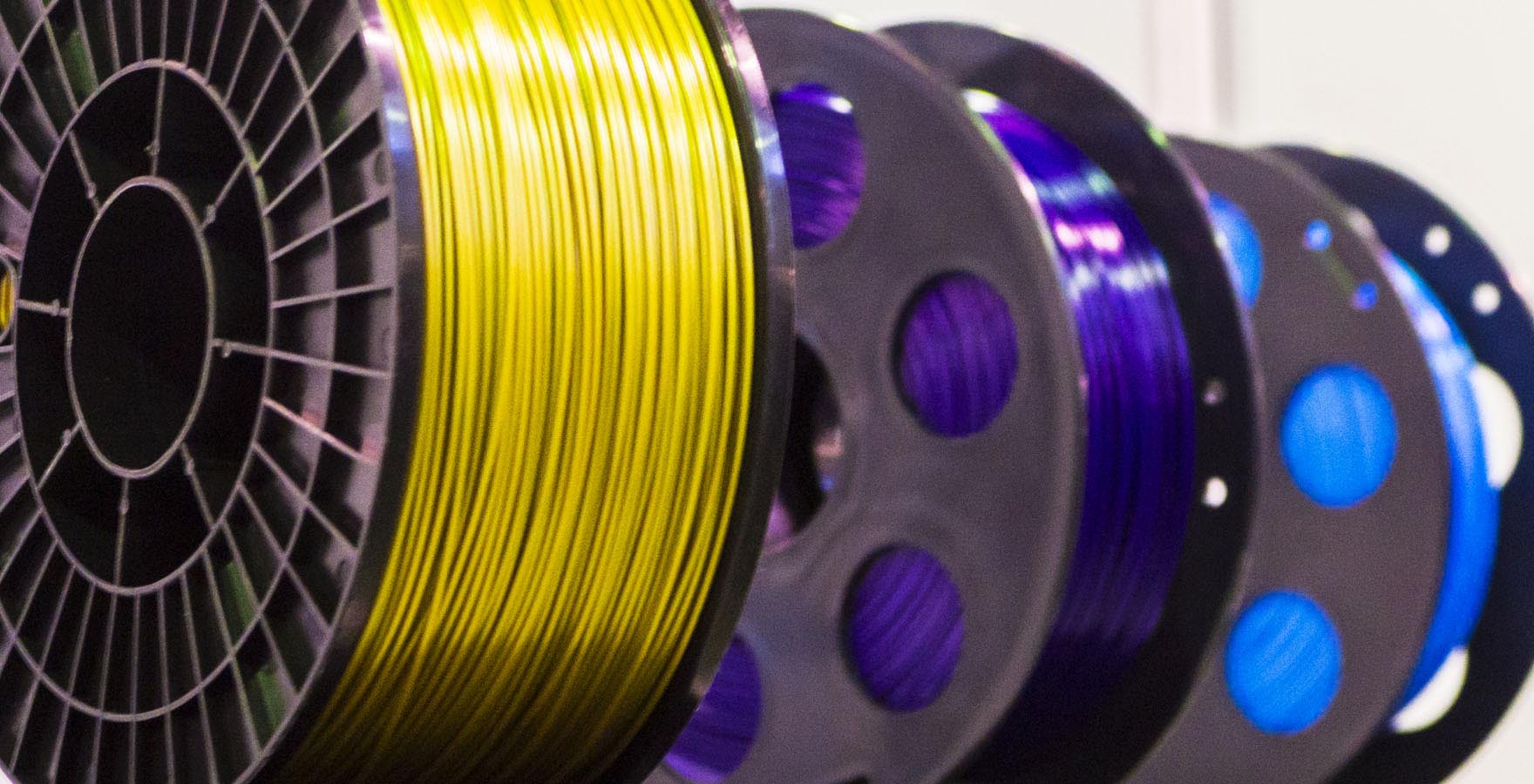

All the above 3D Printing Materials can be bought in reels where 3D filament is wrapped around as line. It is key that 3D Filament reels are stored in a low humidity environment to avoid bubbles in the final object. There is a big variety in 3D Printer filament colours and there are also filaments that can change their colour on different temperature or light.